Overview

1 Liverpool Street, London.

Part of the process for the demolition of the Liverpool Street building, involved the erection of a hoarding around the perimeter to protect the public from the site works.

John F Hunt utilised the existing concrete Kentledge blocks inherited from Crossrail’s Elizabeth Line hoarding and re-used them at the Liverpool Street site. This avoided the need to fabricate new blocks and provided an opportunity for carbon saving, contributing to the ICE zero carbon emissions goal.

Quantifying the Carbon Saving

To be able to quantify the amount of carbon saved from reusing the blocks, three different scenarios are used for comparison purposes:

• Scenario 1: New Concrete Blocks, Timber Frame and Plywood Sheeting

• Scenario 2: Concrete Blocks with 70% GGBS, Reused Timber Frame and Plywood Sheeting

• Scenario 3: Earth Friendly Concrete, Reused Timber Frame and Plywood Sheeting

Scenario 1: New Concrete Blocks, Timber Frame and Plywood Sheeting

This needed complete fabrication with raw materials obtained directly from the suppliers and delivered to site: timber, plywood sheets for the mould and reinforced concrete mix utilising 100% Portland cement.

As the source of materials originated directly from the supplier, the carbon contributed from sourcing the materials is taken into account.

Scenario 2: Concrete Blocks with 70% GGBS, Reused Timber Frame and Plywood Sheeting

This sees the blocks made on site using Ground Granulated Blast-furnace Slag (GGBS), which originates as a by-product from blast furnaces when processing iron ore into iron and is a cementitious material, replacing 70% of cement needed to make the blocks.

GGBS is considered a green construction material, as production involves less energy and does not require exploitation of raw material.

The fabrication of the blocks incorporates reuse

of existing plywood and timber to construct the moulds on-site. The plywood sheets and timbers were re-purposed from an unsafe site hoarding. This contributes to overall reduction of embodied carbon.

Scenario 3: Earth Friendly Concrete, Reused Timber Frame and Plywood Sheeting

This uses alternative components and chemicals to replace the Portland cement option, with an Earth Friendly Concrete (EFC).

EFC uses a geopolymer binder system made from by-products of blast furnace slag and fly ash

and provides better properties than concrete, such as improved durability, lower shrinkage, fire resistance and also offers a reduction of up to 63% of embodied energy compared with standard concrete mixes.

This, combined with the re-use of carbon saving practices, offers a new ‘green’ method of making concrete kentledge blocks.

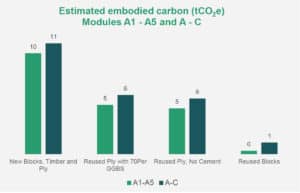

The chart indicates that fabricating the same number of blocks from new materials exhibits

the most embodied carbon. With 100% Portland cement, an estimated total of 10,000 kgCO2e

is produced, but when taking into account the

‘Cradle to Grave’ scenario, it is expected the embodied carbon will rise to 11,000 kgCO2e.

Where additives such as GGBS are used with existing timber and plywood on site, the embodied carbon is halved to 5,000 kgCO2e. A similar estimation is produced if the blocks are made from EFC.

By utilising the blocks from Liverpool Street, the project saved from 5,000 to 10,000 of kgCO2e.

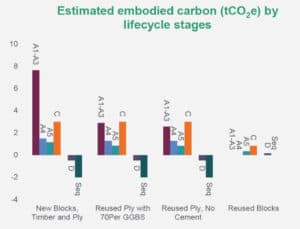

Estimates by Life-cycle Stages

Further modular breakdown of the components as shown in the Life-cycle Stages chart, indicates that most of the embodied carbon is generated at the production stage (A1-A3) of the base materials

i.e. concrete mix and raw wood into timber and plywood sheets.

Embodied Carbon Assessment

To calculate and compare the embodied carbon for each scenario, we used the latest Structural Carbon Tool produced by the Institute of Structural Engineers (IStructE) and data provided by the Institution of Civil Engineer (ICE) Data Base.

Estimated Embodied Carbon Modules

Modules A1-A5 represent the amount of embodied carbon of each scenario from

‘Cradle’ to ‘Practical Completion’. This covers raw materials needed to make the product, transportation, manufacturing and construction.

A definitive example is shown by making concrete and mould materials from new, therefore contributing 60% of the total embodied carbon of the concrete blocks.

By reusing the timber and plywood sheets and using an alternative to Portland cement, a drastic decrease in embodied energy can be observed.

By simply replacing cement and reusing available materials on site, the carbon generated during production of the blocks can be reduced by up to 63%.

In the remainder of the module A4, A5 and C, there is no drastic change as all have similar construction and end of life processes.

Reusing concrete blocks does not produce any embodied carbon as there is no production stage, however a slight increase will occur at ‘end of life’ where the blocks have to de-constructed and disposed of.

Estimated Carbon Saving by Equivalent

By reusing the concrete blocks, the Liverpool Street project produced a significant sustainable benefit, saving 40 tonnes of concrete and 1.1 tonnes of wood, equalling 11,000 kgC02e. Equal to one of the below:

12 one way flights from London to New York

6 people’s meat, dairy & beer consumption in 1 year

3 average family cars running for a year

Carbon Saving on 2030 Targets

The chart shows that reusing the blocks only generates 11 kgCOe/m². This is well below the targets specified by the SCORS, LETI and RIBA. The other schemes result in exceeding all the embodied carbon targets.

Using EFC and partial replacement of cement is well below the LETI commercial target. But further innovation in production is needed to attain all targets, as making concrete blocks with 70% GGBS, reusing plywood and timber, still exceeds the target specified by RIBA’s Non-Domestic Target and SCORS Target.

EFC (no cement concrete), also requires further innovation so the scheme is fully in-line with the 2030 embodied carbon target, as it currently exceeds the SCORS target.

Key Benefits of Reusing the Blocks

Below is a summary of the advantages of reusing concrete blocks in other projects for carbon saving.

• No virgin materials are required

• No carbon is emitted from any transportation

• No heavy lifting plant required, just use of a pallet truck

• No waste products generated

• No allocated site area for fabrication

Using these methods on projects going forward, John F Hunt is on target for lowering its Carbon Emissions to the current required levels by 2030.